There is quite a bit of buzz about m

ultiphysics lately. In very simple terms,

multiphysics refers to an analysis that involves more than one physical discipline. For example, a thermal stress analysis is a classic example of a

multiphysics application.

However, when vendors are bragging about their

multiphysics capabilities, they are usually referring to a more sophisticated type of

analysis. Take fluid-structure interaction (

FSI), for example. This typically refers to a coupled analysis where the fluid flow field is solved and the forces and pressures are mapped onto a structural mesh and the deformation is solved. The mesh is updated, the fluid solution is resolved and results are mapped over again and the cycle repeats itself. This type of capability is still in its infancy. It has applicability in some very specific applications, but in general, it is a very sophisticated type of analysis. These types of problems are only being tackled by the select few power users that happen to know both the

CFD and Structural simulation sides of the house.

So, why is this type of simulation so difficult? There are many reasons. Let's start off with the mesh. Typically, a

CFD simulation has a higher mesh count and interpolating the structural (coarser mesh) results onto the finer

CFD mesh can be a challenge, especially as the structural mesh deforms. The next challenge is the non-linear materials. Often the structural materials are very soft and their deformation characteristics are non-linear. Last but not least, the analysis is intrinsically transient. The time step required by both the

CFD and Structural side are quite different. So, controlling this and selecting the appropriate time step is important. Clearly, the user needs to know the

CFD program very well and the Structural program just as well. Not to mention the intermediate program that allows for the communication between the two. There are often third party applications, such as

MPCCI, used to communicate between the two solvers. There are vendors, such as

ANSYS, that have the capability but it is still for the extreme power user in the group.

Up to this point, it should be pretty clear that there is nothing "upfront" about m

ultiphysics. This is partially true. Design guys can use Upfront simulation to solve traditional M

ultiphysics problems in a very simple way. For example, we can always run the models "uncoupled". This simply means we can run the

CFD side of the problem and use the results as a boundary condition to the structural side of the problem. We end the cycle right there. We do not then go back to the

CFD model and update the mesh and resolve and continue. The uncouple approach can give some very insightful results without all of the complexity of solving the whole enchilada.

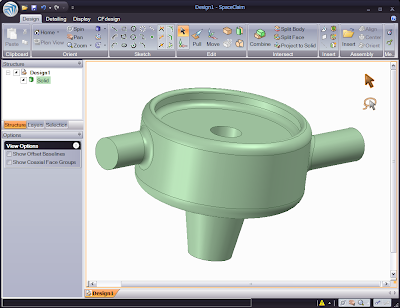

For example, we can run an Upfront

CFD analysis and check forces/pressure on the walls to get an idea of the structural impact the flow has on the device. We can then estimate the load that can be applied to an Upfront Structural simulation to take it to the next level. It would be even better to actually map the results on an element by element basis from the Upfront

CFD tool to the Structural solver. This process is very common and should be a click of a button.