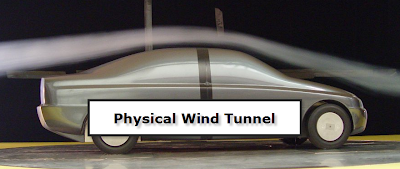

“For example,” he says, “wind tunnel or tank testing often is not all that expensive [when] compared to setting up and running CFD analysis. It is often easier to make the design iterations by playing around with a handful of clay and turn the wind tunnel back on, than it is to change the computer model and rerun the CFD analysis. But structural analysis of a large building design has to be done virtually. Physical analysis is economically impossible.”

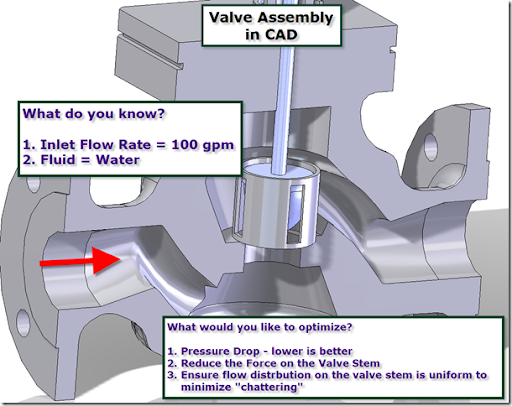

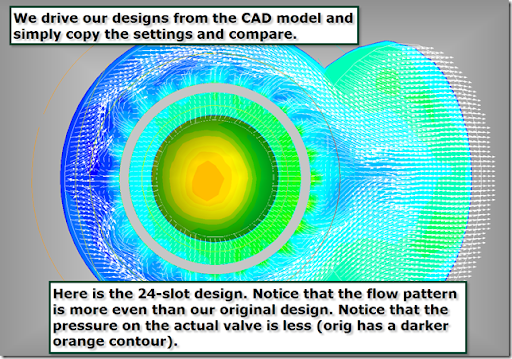

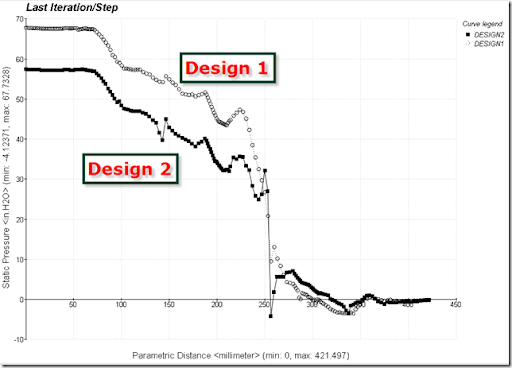

He was designing a brand new line of poppet valves. He was responsible to ensure the pressure drop was within a certain range, as well as determining the spring needed to maintain stable flow over a wide range of flow rates. His ultimate goal was to have three prototypes (3 different sizes) ready to be outsourced for final physical testing. I asked how much were the outsourcing costs? $8k for three...whoa! Seemed steep to me, but I am all about virtual reality, I suppose.

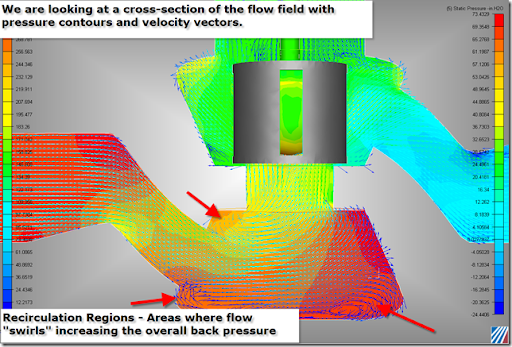

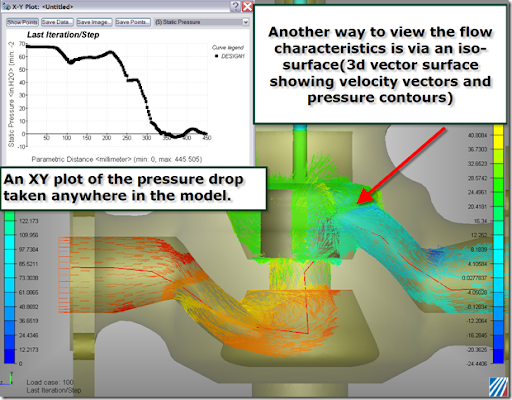

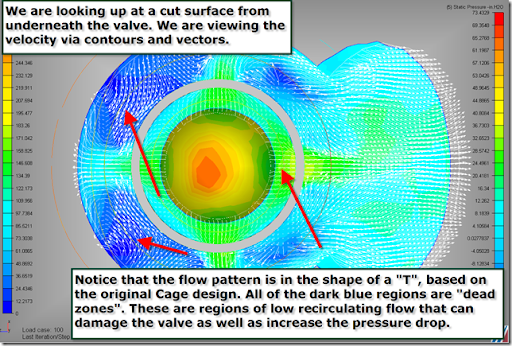

So, let's say you didn't perform an Upfront simulation of the model and your three original designs were not up to snuff. So, you had to re-do the prototype testing. You have just justified the $$ for an Upfront CFD tool. But this is really just the tip of the iceberg. In reality if you had the simulation tool in place you could confidently pay for one round of validation testing at the end of the design cycle. But, more importantly, the simulation models would allow for innovative design that is not possible in the physical testing world. You aren't able to get in there and peel things away to see inside where the action is happening in a wind tunnel. You are limited on the data available and you induce inaccuracies with the measuring devices.

So, back to the article at hand. I think I understand where the guy was coming from. In the past, CFD was the big gorilla in the room. Everyone was afraid to go near it. It was too "expensive". Things have changed drastically over the years. More and more everyday. Whether its a wind tunnel, a flow bench or a thermal chamber or even a thermal camera, there are significant investments of time and materials required.

My friendly advice is to fire up Google and do a search for Upfront CFD.