One of the major benefits of my job is visiting companies all over the world from various industries. Although I am excited about our product and services, my favorite part of the meeting is when I am granted a tour of their facility. It never gets old to walk around and get a view of the inner workings of a prospective customer. It's like being a kid in a candy shop. Fellow engineers are super proud of what they do and get really excited showing off their designs. I get to ask a 1000 questions and learn a great deal about the challenges that companies face. The challenges are all very similar from a fluid flow and heat transfer perspective, even though the industries are quite different.

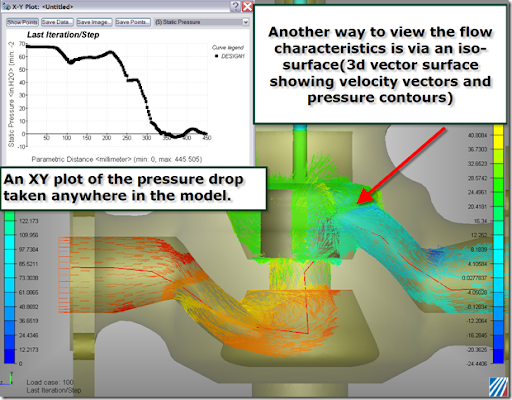

We typically get back to the conference room and now its our turn to show off how we can help their business. I love showing off our software. It is super visual and we can create really cool images that show some valuable insight that is impossible to capture in a test facility. The audience is almost always super receptive to the demo and usually have some really interesting questions. So, we go through and show all of the various ways to understand the fluid flow and thermal characteristics of a representative model.

After a round of high-fives (not really), we get down to business and discuss how to move forward and implement Upfront CFD into their current process. A common question I ask is, "if you had an Upfront CFD tool right now, what is the first thing that you would want to simulate?" More often than not, a common response is, "we have this new design and we would love to know the pressure drop (deltaP)". This is usually followed by an awkward silent pause. Hmm...all the cool stuff that I just showed and you want a deltaP. I think it has to do with a certain comfort level. The deltaP is a common thing they get from physical testing, so they can relate to that value. We can absolutely provide an accurate pressure drop on your device.

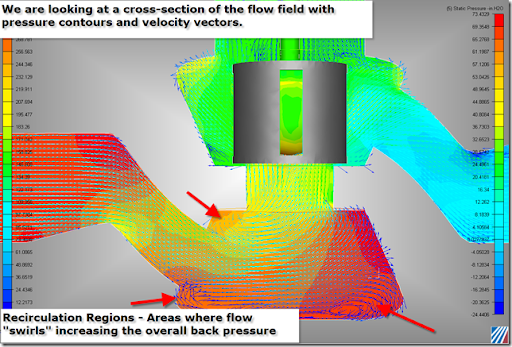

But once you determine the deltaP, then what? There seems to be a disconnect between the fluid flow characteristics and the pressure drop. But in fact, these two are obviously dependent on one another. If you optimize the flow characteristics, you can optimize the pressure drop. So, what does that mean? If you eliminate recirculation regions, reduce separation points and control the impingement regions, you can reduce the pressure drop. How can you do this with physical testing alone? Once you compute the pressure drop, how do you know what to change?

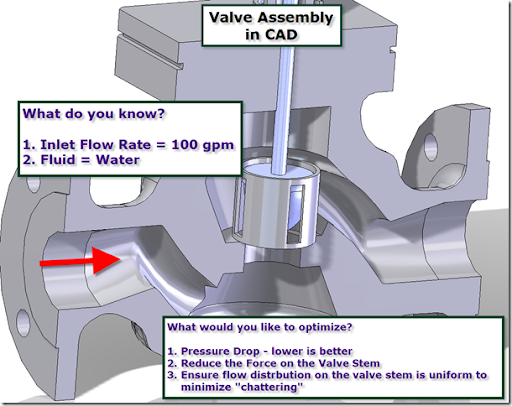

Proof is in the pudding -let's look at an example. We'll keep it simple.

We take the model directly into CFdesign and apply "what we know", let the software automate the rest and click GO! Let's see how we can optimize the design.

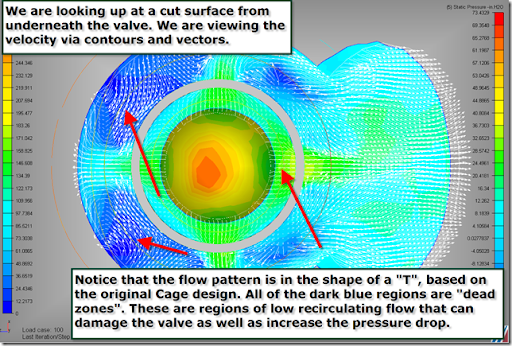

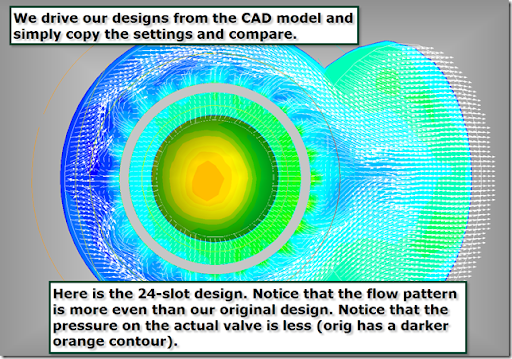

Okay, so I am have a great time with Snag-It. But the point is that Upfront CFD gives you so much more insight to your designs than just a pressure drop value. The key to Upfront CFD is that you get the Pressure drop value, but more importantly you are now in a position to improve the design based on the knowledge that you have gained. Upfront CFD allows you to innovate, testing is there to validate. Based on what we have learned above, we need to reduce the pressure drop and attempt to "even out" the flow field in the area of the valve stem. The original design had 4 cut-outs, "what-if" we increased that to 8, 12, 16 - even 24? Let's make the change and find out.

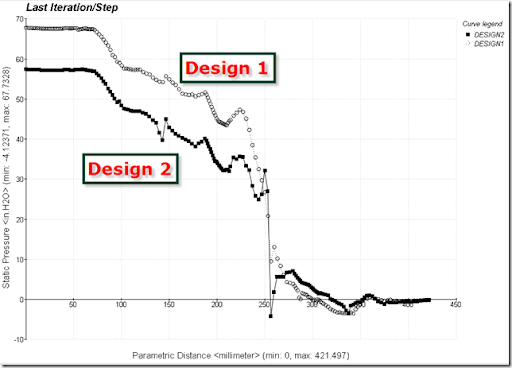

But what impact does the 24-slot design have on the overall Pressure Drop? Let's compare.

We can plot the pressure drop and make an apples to apples comparison. We see that the final design satisfies all of our criteria. We were able to reduce the force on the valve, ensure that the flow is uniform in the vicinity of the valve stem and reduce the overall pressure drop of my system. I was able to do this in the course of a couple hours today. I ran 5 different "what-if" scenarios and compare. Upfront CFD not only gave me my pressure drop, but it allowed me to see from every angle what impact my design change was having on the performance.

No comments:

Post a Comment